Food sorting and steam peeling machines and integrated post-harvest solutions

TOMRA Food offers industry-leading sorting, steam peeling and integrated post-harvest solutions.

For fresh produce and processed foods.

For vegetables, fruits, nuts, meat, fish, confectionery, grains and seeds and petfood.

For protecting food safety, by removing foreign materials, product defects, and cross-contamination.

For achieving consistently high product quality, precisely meeting customers’ specifications without over- or under-delivering.

For reducing food waste, increasing yields, and improving profitability.

For solving today’s challenges, but also for futureproofing food businesses so that they remain competitive in the years ahead

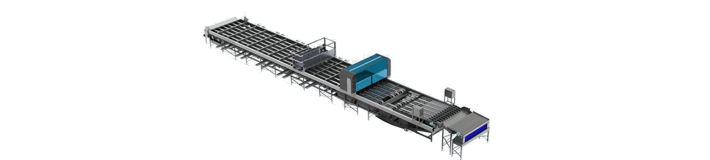

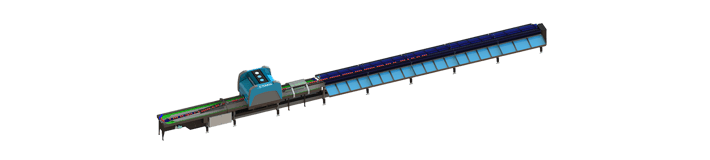

Our food sorting and grading solutions

InVision2 with LUCAi

Spectrim with LUCAi®

TOMRA 3A

TOMRA 3C

TOMRA 5A

TOMRA 5B

TOMRA 5C

TOMRA 5S Advanced

Blizzard

Nimbus BSI+

Sentinel II

TOMRA Neon

Zea

Cascade Singulator

Color Sorter

CURO

KATO260 and LUCAi®

Rotofiller dry bin filler

Small Fruit Sorter with InVision2

Single and Dual Lane Sorters

Soft Sorter

Our food steam peeling solutions

Eco Steam Peeler

Odyssey steam peeler

Orbit Steam Peeler

Our integrated post-harvest solutions

Manual and semi-automatic packing products

Line control and product tracking system

Steam peeling

Get in touch

Operational costs continue to increase, and every little saving makes a difference.

Our automation works smarter, wastes less, and optimizes your lines to ensure quality is consistent and potential recalls are a thing of the past

Speak with us to learn how you can make Every Resource Count!™