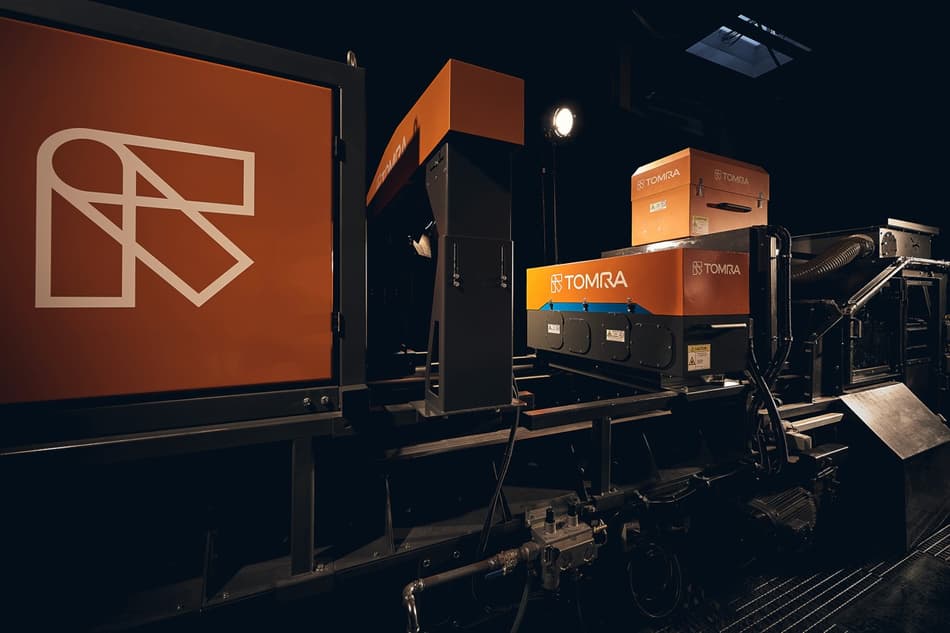

AUTOSORT™ SPEEDAIR

High-speed, intelligent sorting of plastic films and lightweight packaging

-

Closed-loop laminar airflow

-

High throughput up to 6 m/s

-

Low risk of material blockages

-

Open conveyor system, no hood

-

Highly efficient FLYING BEAM™

Accelerate recycling rates and purity levels for plastic films and lightweight packaging without unnecessary downtimes.

Utilizing laminar air flow to stabilize lightweight objects moving along a high-speed conveyor belt, AUTOSORT™ SPEEDAIR instantly identifies high-value materials and remove impurities. The closed-loop fan driven system delivers optimized air handling for lower installation and running costs.

With belt speeds up to 6 m/s, the high throughput sorter features our newest integrated light source with continuous signal correction and intensified light distribution across the entire belt width. Moreover, its machine intelligence combines information to identify chemical properties and molecular differences in the materials for improved accuracy and sorting performance.

The machine’s advanced design allows for an open conveyor system reducing downtimes caused by material blockages in traditional conveyor belt covers. What’s more, it’s connected to the TOMRA Insight platform – a cloud-based service that enables your operations with secure remote status monitoring, process control and data validation.

AUTOSORT™ SPEEDAIR is available as solutions bundle (core device, conveyor belt and catcher hood) or as an add-on device to an existing AUTOSORT™ machine setup.

features

-

SHARP EYE™ Technology

-

DEEP LAISER

-

TOMRA Insight

-

Intelligent Object Recognition

Downloads

- Title

- Description

- Size

Applications

Plastics

We help the world recycle plastics through sensor-based sorting systems that instantly detect and remove contaminants from all types of polymers.

Packaging

We enable circularity with advanced sorting technologies that effectively recover post-consumer packaging waste for recycling.