Black figures in plastic recycling are feasible

At IFAT, you stated that the recycling industry must start making money. Isn't the industry already flourishing?

Dr. Volker Rehrmann: You are right – things are starting to look up. However, until now, recycling has not been a profitable business: virgin oil prices were lower than recycled material, which means that recycled material had no market value. Now, as legislation and policy are coming into place, the market looks much more attractive. The shift towards investing in modern recycling processes is profitable since consumers now support sustainable consumption both morally, and financially.

The responsibility lies with the legislator. Is that enough?

Dr. Volker Rehrmann: Recycling and recycled content targets are gradually gaining ground. Brand owners are committing to meet these targets and to take consumer demands seriously. What is still missing, and here we should act quickly, are appropriate capacities for high-quality recycling. We need to place even greater emphasis on effective sorting and the expansion of facilities for advanced mechanical recycling. In other words: we need the necessary infrastructure now so that this new market can flourish.

Polymers are a challenge for ecologists. To what extent does technology allow for economic and environmentally sound recycling?

Dr. Volker Rehrmann: We should be careful here: plastic is not the problem. In fact, plastic is a very useful material that protects food that might otherwise rot prematurely, and because it is suitable for light transportation, it can also reduce carbon emissions. Its versatility makes it a favorable choice for a variety of use cases.

The real problem is plastic waste. We need to get better waste management systems into place so that we can collect, sort, and recycle more material. And, yes, the technology exists today. Whether basic or advanced mechanical recycling, the technologies are already used globally and have proven that efficient recycling of plastics, as well as other materials, is possible. Our task now is to invest in infrastructure to increase the capacity of high-quality recycling so that the market demands I mentioned before can be met in a financially and environmentally friendly way.

So, collection and sorting seem to be the two crucial points in plastic recycling?

Dr. Volker Rehrmann: That’s correct. In order to level up plastic recycling, we need to introduce holistic approaches at scale. Along with the environmental consultant, EUNOMIA, we have developed a model that uses existing technology to maximize the collection of material. The model is called Holistic Resource Systems and includes deposit return systems, separate collection for specific materials, and mixed waste sorting.

What does Holistic Resource Systems look like in detail?

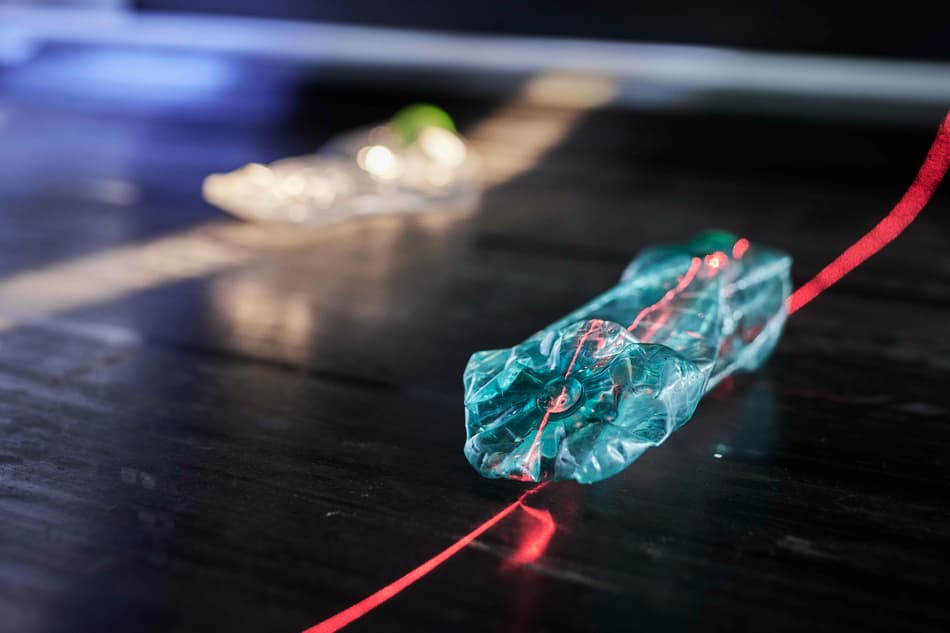

Dr. Volker Rehrmann: The first pillar of this concept is deposit return systems (DRS), which is proven to be the most efficient solution for collecting beverage containers, with an average collection rate of 94%. In Germany, collection rates are even higher, at 98%. Along with reducing litter, this system is indispensable in meeting Europe’s Single Use Plastic Directive, which went into effect July 1st, 2021. We will see these systems go into operation across Europe during the next few years in order to meet this policy

The second pillar is the source separation for selected materials: organic, textiles, e-waste, paper, and glass (if not collected through DRS). The reason for this is to reduce impurities in mixed waste as much as possible and to maintain the integrity of materials so that they can be recycled and reused.

The third pillar is the gold mine. In Germany alone, almost 40% of packaging ends up in mixed waste – the black bin. Generally, this valuable material is being lost to incineration, which means the damage we are causing is two-fold: in principle, we are burning fuel and resorting to virgin oil to produce more plastic.

Are you convinced that better sorting will largely solve the problems of plastic recycling?

Dr. Volker Rehrmann: Better sorting is important and necessary, but it is only one of many measures. First, we must improve the way we collect material before we can efficiently sort it. And, of course, we can only sort to the extent that the material allows us to. All too often, we have to deal with packaging that is made of a variety of polymers, such as many beverage bottles in our supermarkets that are covered in shrink film. The more polymers an item consists of, the more difficult it is to sort and recycle. Therefore, manufacturers must design products with recyclability in mind.

So, the responsibility lies with the packaging companies?

Dr. Volker Rehrmann: We should also invest in better washing, a process called "Super Cleaning", and extrusion, to get recyclates that match the quality of virgin material. Improved sorting alone cannot solve the current challenges.

What role does advanced sorting technology play in plastic recycling?

Dr. Volker Rehrmann: We have always worked with AI to achieve very good results. However, now we are examining and expanding into difficult applications through the use of Deep Learning technology. This technology allows sensors to make sorting decisions based on the object’s form and texture. It is very promising for the waste management industry because it offers a greater level of detail in the sorting process.

Could your sorters help recover plastics from mixed waste if these materials are disposed of in one bin?

Dr. Volker Rehrmann: Generally, an existing and well-functioning dual system should be optimized to get more out of it. However, this takes time, and we should complement it with mixed waste sorting (MWS) to avoid losing material. In addition, as mentioned before, even in regions where a dual system is in place, many plastics are not disposed of in the yellow bin, as they are not packaging and it might not be clear where these should be disposed of. This is where residual waste sorting can help. Where there is no system, like the dual system, we recommend analyzing the country’s current system and defining the most efficient approach to holistic resource management.

One problem with the collection of recyclables is in apartment buildings where, due to a lack of social control, waste is often disposed of in an unsorted manner. A solvable problem?

Dr. Volker Rehrmann: This is a very good example of where mixed waste sorting works wonders. In fact, as megacities become more common, MWS will become increasingly important.

In Norway, TOMRA is already testing mixed waste sorting with remarkable success, even with plastics. A model for Germany, too?

Dr. Volker Rehrmann: It’s important to point out that this is not a trial by TOMRA. Instead, various municipalities, including those in Norway, Sweden and even Greece, among others, decided to establish individual processes to recover valuable materials from household waste. TOMRA was simply the partner they chose to do it with. The results show that valuable materials that would have been lost to incineration or landfill could be recovered and made available for recycling.

Let’s go more into practice…

Dr. Volker Rehrmann: Two operations in Norway (IVAR and ROAF) are in 1st and 2nd place in terms of the amount of plastics recovered from all municipalities in Norway. Additionally, some areas that added MWS to their waste management system more than doubled the amount of packaging that was collected. Rotterdam, in the Netherlands, increased the amount by 12 times – most likely because this area has many multi-family homes and much of the material was simply being lost.

From TOMRA's point of view, what can municipalities and waste management companies do to improve the collection results for plastics?

Dr. Volker Rehrmann: We see that the collection rates in source separation schemes reach saturation. Although we trust that educational campaigns can improve the situation, it will most likely not be enough to make a change. Only mixed waste sorting can enable this change and capture more recyclable materials.

Referring back to the initial question: What solutions does TOMRA offer to improve the bottom line in plastics recycling?

Dr. Volker Rehrmann: On the one hand, it is our technology. On the other hand, it’s our collaborative approach. We work across the plastics value chain to find and implement effective solutions as quickly as possible. This kind of collaboration is relatively new, but we have all realized that if we want to accelerate the transition towards a circular economy, each of us must play our part. A clear example of this is the advanced mechanical recycling demonstration plant in Lahnstein. Here, we were able to work with our partners to bring existing technology and know-how together to produce high-quality recyclate from both source separated and mixed waste. It turns out that the quality from both sources is exactly the same. This means that regardless of the source, we can produce what the market needs. Now.

The interview has exclusively been published in the October edition of Entsorga.