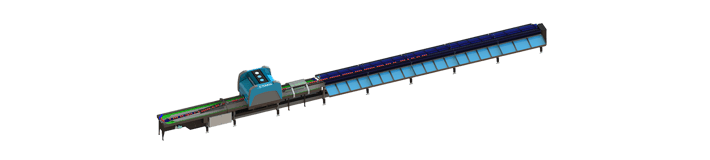

TOMRA 5S Advanced

TOMRA 5S Advanced builds on our Multi Lane Sorter’s class-leading performance. Designed for hygienic operation, it has toolless cleaning and sanitization, and food safe contact areas.

Single and Dual Lane Sorters

Single and Dual Lane Sorters are ideal for small-to-medium packhouses but also connectable to our larger Multi Lane Sorter. They can pack into a wide variety of packaging types.

Line control and product tracking system

Through digital transformation, usable line data leads to better line control and decision-making. This leads, in turn, to greater efficiency and profitability.

Rotofiller dry bin filler

The Rotofiller’s infeed belt and optimized geometry are designed for the gentle bin filling of delicate fruit in bulk at high levels of throughput.

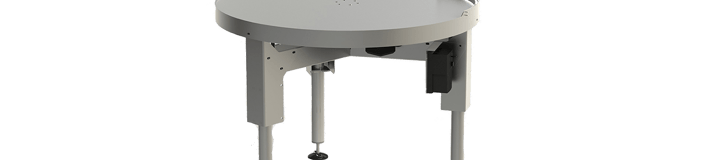

Manual and semi-automatic packing products

For manual and semi-automatic packing, our products offer the full solution: rotary packing tables, and tray, box, and bin fillers.

Get in touch

Operational costs continue to increase, and every little saving makes a difference.

Our automation works smarter, wastes less, and optimizes your lines to ensure quality is consistent and potential recalls are thing of the past.

Speak with us to learn how you can make Every Resource Count!™

How kiwifruit packhouses can keep pace with the industry's changing demands

Packing lines can increase throughput, improve product quality, and enhance profitability with modern sorting and grading solutions. Tim Grieve, TOMRA Food’s Global Category Director for Kiwifruit, explains.

Service and support

With service centers and support located across the globe, TOMRA Food provides a comprehensive service offering to our customers, ensuring you have the proper support at the right time, empowering your business to succeed.

More about service and support

.jpg)