MAKING EVERY PIECE OF FOOD COUNT

Every Resource Counts™

We are dedicated to improving and safeguarding food production bit by bit.

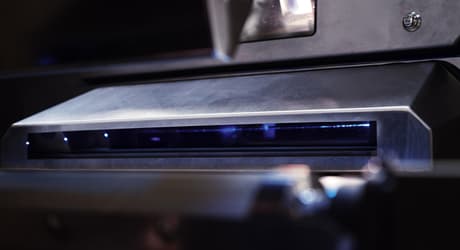

We develop, design and adapt sensor-based food sorting and steam peeling machines and integrated post-harvest solutions which protect and empower food businesses.

We turn complex information gathered by our machines into valuable, usable data which can bring further efficiency improvements.

We also strengthen our customers’ businesses by sharing our world-class know-how in industrial food processing and the challenges specific to each different food category.

These solutions create sustainable value – today and for future generations – because every resource counts.

To protect and empower your food business, join us on our sustainable journey!

Find your Food solution

Fruit

Nuts and dried fruit

Potatoes

Protein

Seeds & Grains solutions

Vegetables

Service and support

Benefits of TOMRA's sensor-based sorting machines and integrated post-harvest solutions

Advancing intelligence

Brand and consumer protection

Safe food of consistent, high quality

Leading-edge optical sorting for a competitive advantage

Trusted togetherness

Maximized profit and yield

Reducing food loss

Roots of knowledge

Year-round global and local support

TOMRA Food technology

Get in touch

Operational costs continue to increase, and every little saving makes a difference.

Our automation works smarter, wastes less, and optimizes your lines to ensure quality is consistent and potential recalls are a thing of the past.

Speak with us to learn how you can make Every Resource Count™!