Peanut sorting machines

TOMRA peanuts sorting

Customer story

QINGDAO JIXING FOOD, CHINA

Pingdu, a city in Shandong province, enjoys four clear seasons, sufficient sunshine and is one of the three main peanut-producing areas in China. The natural and high-quality raw material found here has seen an influx of peanut processing companies locate to the surrounding areas. Qingdao Jixing Food exports its products to 17 countries including South Korea, Russia, Japan and the United States, gaining recognition for food ‘made in China’ in the international market.

Read the full customer testimonial

Our peanut solutions

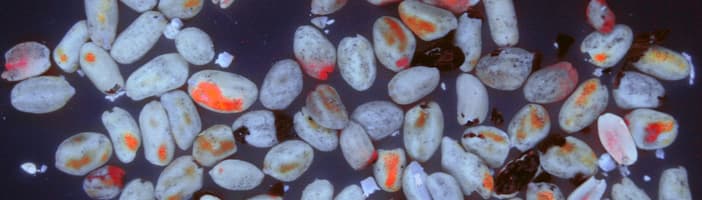

TOMRA 3C

The TOMRA 3C sorts with unrivaled accuracy, detecting the subtlest color and shape imperfections, empty shells, and all manner of foreign materials, including glass and transparent plastic.

TOMRA 5C

Capable of unrivaled foreign material removal, this highly efficient machine is powerful and robust, easy to use and maintain, reduces storage needs, is easily movable, and saves on labor.

TOMRA 5B

Coupling the latest sensor technology with advanced algorithms, the TOMRA 5B belt sorter enables you to reach the most challenging quality targets and yields.

Get in touch

Operational costs continue to increase, and every little saving makes a difference.

Our automation works smarter, wastes less, and optimizes your lines to ensure quality is consistent and potential recalls are thing of the past.

Speak with us to learn how you can make Every Resource Count!™

How nut processors can gain from the latest sorting technologies

It’s not easy for nut processors to ensure food safety or meet customers’ product specifications. For one thing, foreign material and shell fragments can get into the processing line’s product stream. For another, nuts can be damaged by both by external and internal defects which can be almost impossible to detect. There’s also the risk posed by allergens if one type of nut should unintentionally get mixed with another. Yet all of these threats have to be eliminated to protect processors and retailers from product recalls and reputational damage.

This is achievable thanks to the extraordinary effectiveness of state-of-the-art optical sorting machines.

This is achievable thanks to the extraordinary effectiveness of state-of-the-art optical sorting machines.

Service and support

With service centers and support located across the globe, TOMRA Food provides a comprehensive service offering to our customers, ensuring you have the proper support at the right time, empowering your business to succeed.

More about service and support