Challenge us with your material

Test material samples from your operations on our machines. Our sorting experts will help you find the best solution for your needs.

Electronic waste is one of the fastest growing waste streams globally and is projected to reach 74 million metric tons by 2030. Sensor-based sorting of electrical waste and electronic equipment (WEEE) recovers valuable materials such as metals and plastics for recycling. It also ensures harmful components like brominated flame retardants are disposed of properly.

Automated sorting of mixed metals like Zorba and Zurik enables e-waste recyclers a profitable return on investment through the recovery and sale of high purity aluminum, copper, grey metals and brass. Printed circuit boards and thermoplastics can be effectively sorted into clean fractions for marketable products as well.

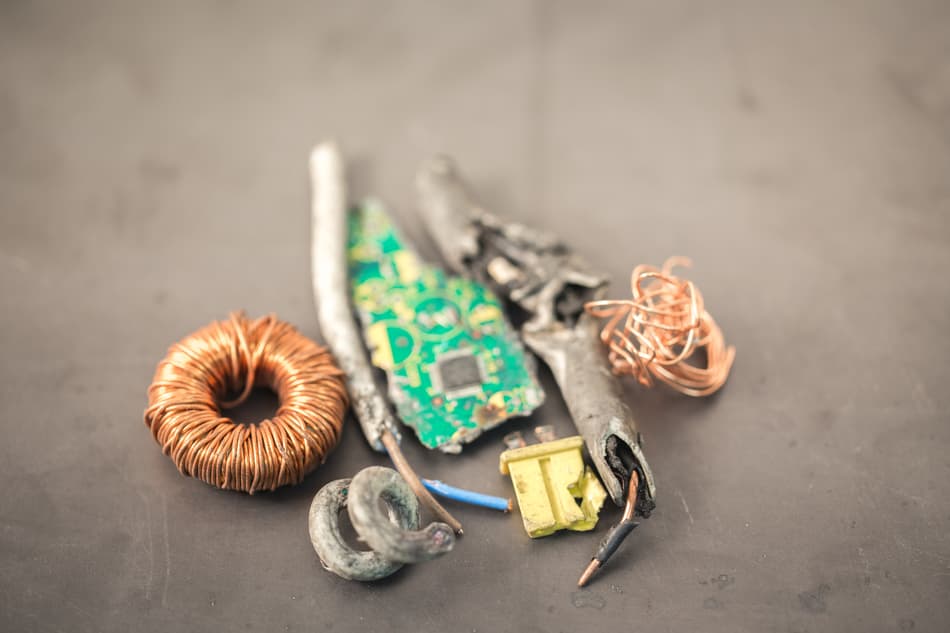

The recovery of copper wire offers recyclers fast and high returns on their initial investment. Wires represent a high-value revenue stream for electronic recyclers, but they can be challenging to sort due to the various shapes and forms.

Our intelligent, sensor-based sorting systems detect copper and produce high-quality insulated copper wire (ICW) fractions by detecting polymer (PVC, PP, PE) and rubber coatings. You achieve higher copper recovery rates thanks to our combination of high precision near-infrared (NIR) and visual (VIS) spectrometry sensors that offer exceptional detection of wires in a mixed scrap metal stream.

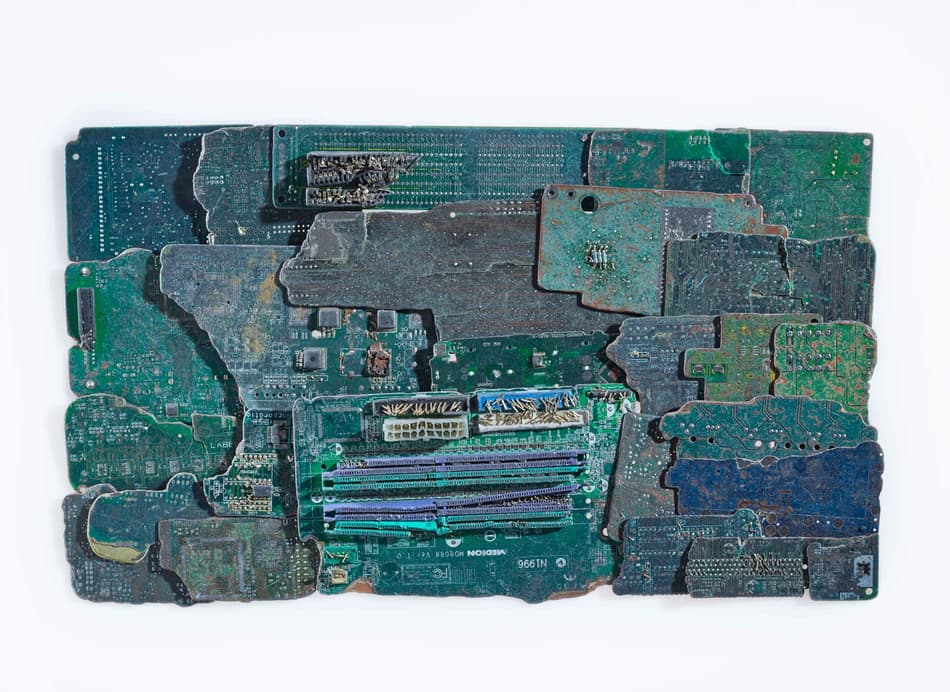

Printed circuit boards are very common in electronic equipment and are used for mounting various components. While PCBs constitute a small share (8%) of e-scrap waste, their precious metal recovery offers the highest revenue source. Recycling PCBs have proven to yield more precious metals like copper and gold than one ton of mined ore.

After device disassembly and shredding, our automated sorting units harness the power of spectral and electromagnetic sensors to detect various sized fractions of printed circuit boards from electronic waste. Contaminants such as plastics, rubber and metals are removed, delivering you high-quality PCB fractions to meet market demands.

Plastics constitute approximately 20 percent of electronic waste but until recently proved challenging to recycle due to the presence of brominated flame retardants. While some thermoplastics in e-waste are recyclable, objects made of complex polymer blends and non-recyclable plastic fractions are typically used for energy recovery.

Our plastic sorting systems with multifunctional sensor configuration instantly detect and separate visible PS, PC, ABS, PVC, PP, PE, PPO, PPE, PBT and PMMA. You also benefit from our object-based recognition technology that distinguishes between overlapping materials, transparent polymers vs glass, and identifies black polymers for maximum plastic yields.

Copper is a fully recyclable and a vital raw material for global supply chains, especially the electronics industry. From printed circuit boards to cables and wires, the recovery of copper in electronic waste is critical to meet the increasing global demands for recycled copper and help preserve this non-renewable natural resource.

Our sensor-based sorting equipment offers exceptional detection of all types and grain sizes of copper objects found in complex e-scrap waste streams. With high sensitivity sensors, contaminants such as lead are detected by characteristics and color variations. Your operation profits from high purity copper granulate to meet market demand.

Approximately 30 percent of plastics in electronic waste contain brominated flame retardants (BFRs). Policies prohibiting the reuse of plastics containing BFRs and banning certain types of plastic waste exports have created an innovative mindset in automated sorting systems.

By combining near-infrared (NIR) and x-ray transmission (XRT) technologies, sorting systems can effectively separate recyclable polymers from BFR polymers. The two-step sorting process successfully removes up to 98 percent of plastics containing BFRs, giving your e-scrap operation high-performance results and new revenue streams.