TOMRA's laser sorter opens new markets for Mikroman quartz mining operation

Turkish Quartz mining company Mikroman Maden A.Ş, established in 1991, first adopted sensor-based sorting technology at three of its processing plants in 2018. It installed three high-capacity TOMRA PRO Secondary LASER sorters and reached its target of improving product quality and increasing capacity at these facilities. At its Kula plant in Manisa province, which requires the most precise mineral sorting, it combined TOMRA’s COLOR and LASER technologies to achieve the best results and recovery with the highest purity levels, as well as creating product of different quality to meet the specific needs of a variety of markets. The solution has consistently delivered the desired quality standard in all categories, while increasing productivity, and consequently reducing waste.

Mikroman Management stated that the collaboration with TOMRA and the use of our LASER and COLOR sensor-based sorting technologies have greatly improved their production quality and efficiency. The company saw the potential to expand its operation and enter new markets with these solutions, as using LASER and COLOR sorting systems allowed them to serve a variety of sectors by changing the quality and chemistry of the micronized and granulated products.

A collaborative approach to addressing a new requirement.

Satisfied with the results achieved at the Kula plant by TOMRA’s PRO Secondary COLOR and LASER sorters with bigger particle sizes, Mikroman asked TOMRA for a solution to process the finer materials and turn them into value.

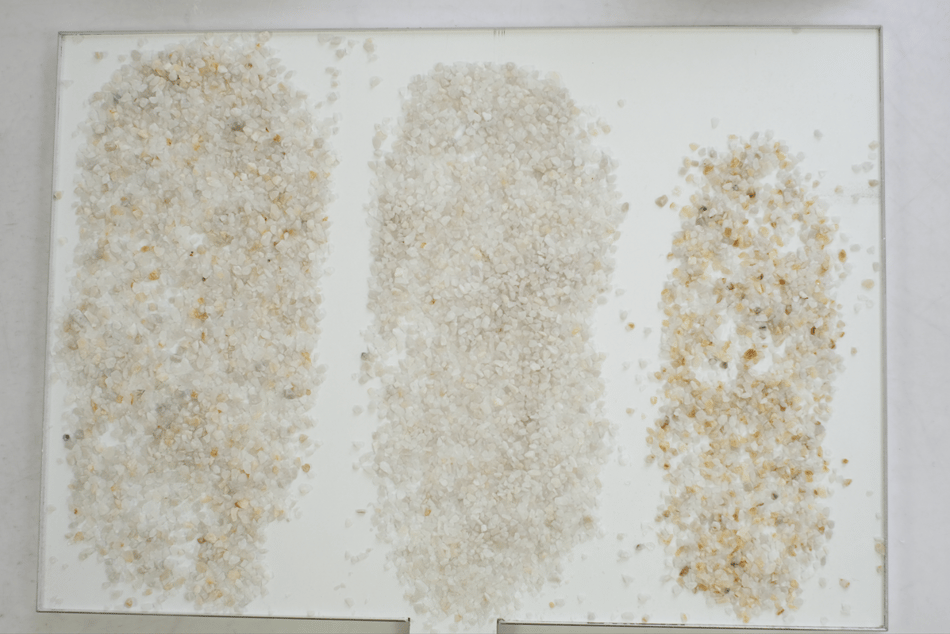

Mikroman was processing particles sizes down to 15mm with a PRO Tertiary COLOR, and TOMRA installed 3 additional PRO Tertiary COLOR sorters for finer particles: two for sorting particle sizes from 2-4mm and one for sizes from 4-10mm to remove colored impurities from the material, which is then processed further in a Micronized plant on the premises. With these sorters, Mikroman is able to diversify its product to provide the different qualities required by the various sectors it serves also in the smaller particle sizes.

On the other hand, the company also wanted the high purity levels achieved with laser technology in grain sizes below 20mm. However, “at the time, the PRO Tertiary was only available with COLOR technology, so we looked into a new product development implementing the TOMRA multi-channel LASER technology in the PRO Tertiary platform,” explains Ines Hartwig, Director Product Management at TOMRA Mining. “With this solution, also white non-quartz impurities like shist, feldspar, shale and calcite can be detected and sorted out to achieve a pure white, high-grade quartz product.”

Ines Hartwig adds: “As Mikroman had already implemented the LASER technology for bigger grain sizes and had experienced its advantages compared to COLOR sorters, it was a perfect fit to collaborate, design and field test this new product. They provided us with the small particle references of product and waste that they expected to sort, and our Engineering team developed the new machine with the support of Markus Dehler, Manager of the TOMRA Mining Test Center.”

PRO Tertiary LASER and COLOR technologies: high quality and accuracy in small size particles.

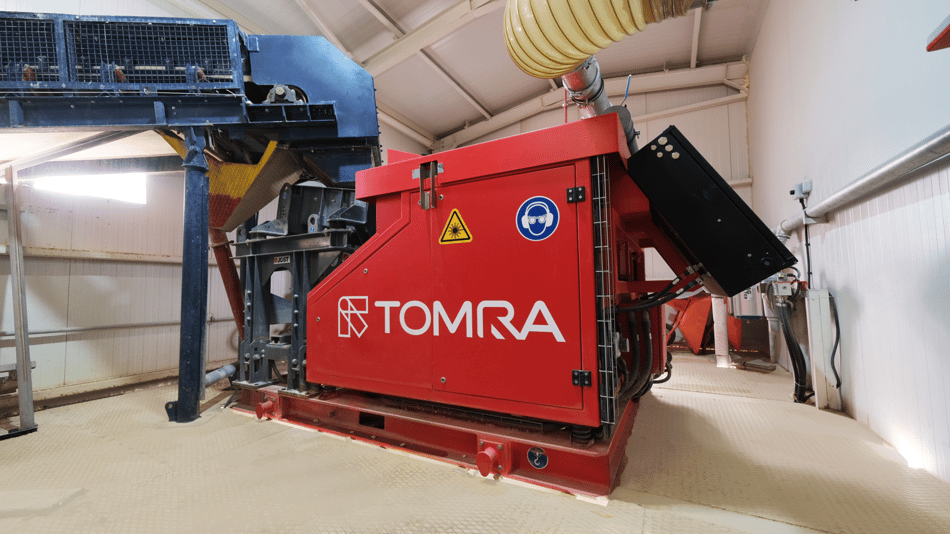

The PRO Tertiary LASER sorter uses the same multi-channel LASER technology as the PRO Secondary platform, but is specialized in detecting and sorting smaller sized material, from 6-32mm. The distance between detection and ejection is minimized and the number of ejectors increased to result in a very precise, effective and efficient sorting and highest product quality and yield.

The TOMRA PRO Tertiary LASER is a low-maintenance, simple and stable platform that has the advantage of being the only one on the market to offer customization of the laser wavelengths to match the specific applications. The development was completed in a short timeframe and a new PRO Tertiary LASER sorter was installed at the Kula plant to process grain sizes 5-15 mm and 15-35mm. The two PRO Tertiary COLOR and LASER sorters combined are consistently removing 98% of impurities in small sizes from 5-35mm, while delivering savings in water, fuel and electricity consumption in the downstream process.

TOMRA technology enables expansion into new markets and growth.

With these investments, Mikroman has expanded its capacity and product portfolio to serve a wide range of industries – composite stone, glass, electronics, metallurgy, paint and ceramics among others – and exports to 15 countries including the United States, Spain, Italy and Israel. Mikroman Management stated that using TOMRA technology has given them the confidence to commit with their customers to deliver a homogeneous and high-quality product.

According to them, the ability to sort all the size ranges offered by TOMRA according to the color and chemistry of the product has allowed Mikroman to become the leading company in the sector, and to hold a large share of 65% of the exports around the world and domestic sales in Turkey. The collaboration with TOMRA has developed as Mikroman’s operation evolved, with the addition of further COLOR and LASER sorters, which now total 18 units across four plants.

Nowadays, there are ten TOMRA sorters up and running at the Yava and Kula plants, one in its Karpuzlu mine in the Aydin province and two sorters at its new Catalca plant in Istanbul. To support its continued growth, Mikroman invested in two brand-new PRO Tertiary LASER sorters: one commissioned at Kula and one at Yava plant. Their latest investment included two PRO Tertiary COLOR sorters and a PRO Tertiary LASER which have been delivered and will soon be installed at the Kula plant.