Automation of URBASER - Las Dehesas Waste Treatment Centre with TOMRA

URBASER, the environmental management company with 128 plants in different Spanish cities, has automated two lines at the Las Dehesas Waste Treatment Centre through the incorporation of six AUTOSORT units.

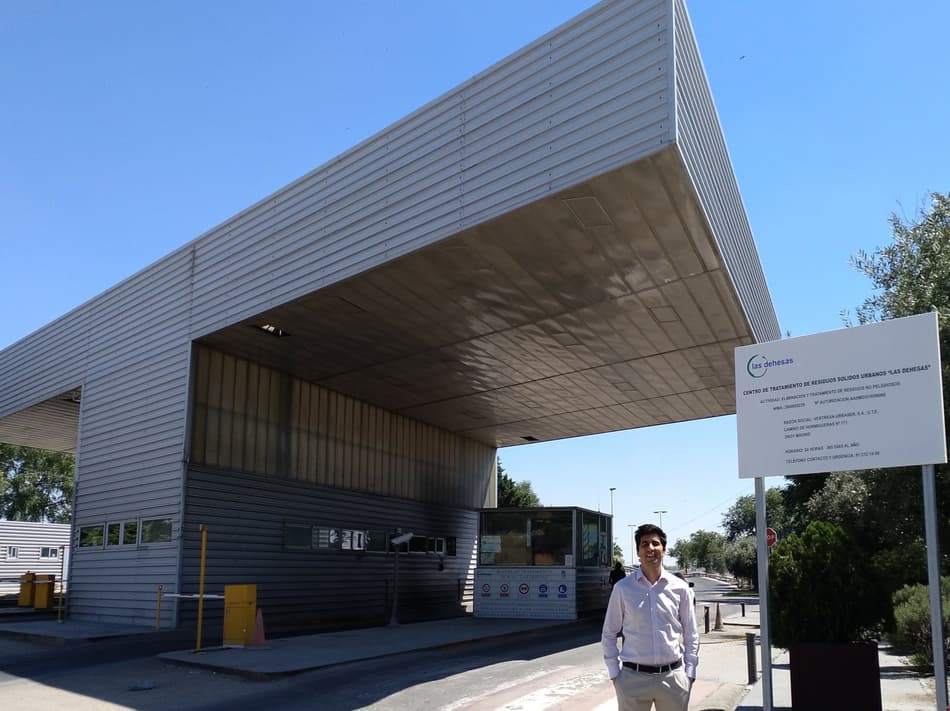

The Las Dehesas Waste Treatment Centre processes materials from both the rest fraction and the packaging fraction of waste collected in the city of Madrid. The facility has a rest fraction treatment capacity of 408,000 t and a packaging waste treatment capacity of 32,850 t.

Las Dehesas has four manual sorting lines for the separation of recoverable materials. Two of these are dual-purpose lines that can be used for both rest and packaging waste fractions. Each of these packaging waste treatment lines processes 7.2 t/h, giving a total annual capacity of 32,850 t/annum.

The upgrading project consisted of automating the two packaging waste treatment lines which can also be used for the treatment of the rest fraction. Six TOMRA Sorting Recycling AUTOSORT units were installed in these two lines in a cascade arrangement.

Two AUTOSORT units (one per line) are responsible for separating recoverable plastics and tetra-brik containers from unrecoverable materials. Subsequently, a further two units (one per line) separate polyethylene terephthalate (PET). Finally, the stream is unified in a single line fitted with one AUTOSORT unit to separate HDPE and another to separate tetra-brik containers, resulting in a mix which is then sorted by the remaining units.

Fernando Cortés Moreno, Managing Director of the UTE Las Dehesas consortium, points out that “it is a robust system, with the necessary flexibility to make changes in the material sorting programme of each unit. Moreover, the performance and efficiency guarantees we were given are being fulfilled and the quality standards established for the sorted materials are being achieved.”

AUTOSORT, a highly efficient piece of equipment

AUTOSORT affords numerous benefits for the recycling sector in the form of state-of-the-art sorting technology. The near infrared (NIR) sensor recognises materials based on their specific spectral properties while the VIS sensor can distinguish all the colours of the visible spectrum. The combination of the two sensors means that these units can meet both basic and extremely complex needs, enabling simultaneous sorting by both material type and colour within a single modular sorting system. The units installed at the Las Dehesas Centre are fitted only with NIR sensors and sorting is by material type, regardless of colour.

“For greater convenience, a central display system was installed to enable the operation of the units to be checked without having to view the display screen of each individual optical sorter. This enables changes to be implemented more rapidly and more precisely,” points out Fernando Cortés Moreno. Mr Cortés Moreno also highlights the simple maintenance requirements of the AUTOSORT units: “Thus far, we can confirm that basic maintenance is simple.”

AUTOSORT units are extremely versatile, with a number of different configuration options. They are easy to use and adapt very well to customer needs. According to Luis Sánchez Vela, “This operational simplicity is very beneficial. It enables operators to adjust the configuration of the unit with ease so that the material to be separated can be changed whenever the need arises.”

Satisfied needs

Apart from the treatment plant, the Las Dehesas Waste Treatment Centre also has a composting plant, a cremation chamber for dead animals, a non-hazardous waste landfill, a leachate treatment plant and a waste-to-energy plant for biogas produced in the landfill. It is, therefore, an important complex and correct day-to-day operation is vital.

STADLER and TOMRA work together in a highly reliable and professional manner, with the former providing the highest standards of installation and the latter supporting this with excellent after-sales service.

“The installation and commissioning of the equipment was carried out rapidly and with highly satisfactory results. And, on the few occasions on which after-sales service has been required to date, the response has been excellent,” explains Fernando Cortés Moreno. “All these benefits have led us to examine the possibility of automating the two remaining rest fraction treatment lines,” he concludes.