Waste sorting products

GAINnext™

AI-powered sorting system with deep learning technology

-

AI waste sorting

-

Identifies hard-to-classify objects

-

Enables new material streams

-

Automates manual sorting

-

Wide application ecosystem

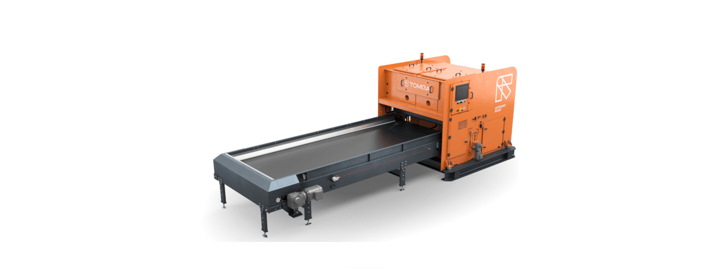

AUTOSORT™

The world-renowed AUTOSORT™ offers legendary sorting performance that stands the test of time, delivering unparalleled throughput and purity rates across numerous applications.

-

Multifunctional sensor configuration

-

Optimized costs & performance

-

Highly efficient FLYING BEAM™

-

Future-proof system design

-

Minimal maintenance

AUTOSORT™ FLAKE

Achieve maximum purity yields for high-end applications such as bottle to bottle recycling

With a combination of our most powerful sensor technologies, AUTOSORT™ FLAKE offers consistent and exceptional sorting performance. Its high-speed valves eject even the smallest contaminates with maximum precision to meet extremely high purity requirements.

-

Constant, ultra-high purity processing

-

High sensitivity electromagnetic sensor

-

Foreign polymers, colors and metal removal

-

Cost effective operation

-

Bottle-to-bottle recycling solution

INNOSORT™ FLAKE

Achieve high-purity recyclable flakes, even from contaminated mixed streams

With a powerful sensor combination that enables simultaneous detection of polymers and colors, the next generation INNOSORT™ FLAKE is an evolutionary and cost-effective design for plastic recyclers worldwide.

-

Flexibility to sort various polymers

-

Unrivaled color sorting performance

-

Increased yield, boosts profit

-

Easy to operate and maintain

-

Simple integration into any plant

AUTOSORT™ RDF

As a world-class technology utilized to prepare substitute fuels, AUTOSORT™ RDF combines built-in machine intelligence and high precision sensors to analyze the overall combustibility of various waste streams.

-

Real-time online monitoring

-

Calorific, water & chlorine analysis

-

Reliable data accuracy

-

Cost effective quality assurance

AUTOSORT™ SPEEDAIR

Accelerate recycling rates and purity levels for plastic films and lightweight packaging without unnecessary downtimes

Utilizing laminar air flow to stabilize lightweight objects moving along a high-speed conveyor belt, AUTOSORT™ SPEEDAIR instantly identifies high-value materials and remove impurities. The closed-loop fan driven system delivers optimized air handling for lower installation and running costs.

-

Closed-loop laminar airflow

-

High throughput up to 6 m/s

-

Low risk of material blockages

-

Open conveyor system, no hood

-

Highly efficient FLYING BEAM™

COMBISENSE™

Effectively sort high value metals with unsurpassed color detection and image processing technology

COMBISENSE™ maximizes the value of non-ferrous metals with color detection and high throughput sorting of zinc grey metals, copper, brass, e-scrap and PCBs.

-

Exceptional grey metal sorting

-

Long-term yield stability

-

High throughput processing

-

Auto-adjusting ejection system

-

Multiple sorting tasks & grain sizes

X-TRACT™ for Wood

X-TRACT™ is a high throughput sorting solution to separate waste wood from complex mixed streams with a capacity of up to 30 metric tons per hour, depending on the material input.

-

Up to 30 metric ton capacity

-

16.000 hour warranty

-

New DUOLINE™ XRT sensor

-

Improved stability and reliability

-

High operational efficiency

AUTOSORT™ BLACK

With its enhanced resolution, AUTOSORT™ BLACK delivers high-purity results and creates tremendous value for recyclers.

-

Sharp material detection

-

Grain sizes from 25 to 120 mm

-

High throughput and purity

-

Easy installation

-

Low maintenance effort

Metal sorting products

AUTOSORT™

The world-renowed AUTOSORT™ offers legendary sorting performance that stands the test of time, delivering unparalleled throughput and purity rates across numerous applications.

-

Multifunctional sensor configuration

-

Optimized costs & performance

-

Highly efficient FLYING BEAM™

-

Future-proof system design

-

Minimal maintenance

FINDER™

FINDER™ is the ideal sorting solution to recover non-ferrous metals lost to eddy current separation.

-

SUPPIXX™ spatial resolution

-

Intelligent object recognition

-

Multifunctional sorting

-

Easy & intuitive interface

-

High throughput for higher yield

COMBISENSE™

Effectively sort high value metals with unsurpassed color detection and image processing technology

COMBISENSE™ maximizes the value of non-ferrous metals with color detection and high throughput sorting of zinc grey metals, copper, brass, e-scrap and PCBs.

-

Exceptional grey metal sorting

-

Long-term yield stability

-

High throughput processing

-

Auto-adjusting ejection system

-

Multiple sorting tasks & grain sizes

X-TRACT™ for Metal

X-TRACT™ maximizes aluminum recycling and processing with x-ray sorting technology (XRT) that separates aluminum from heavy metals in a single step.

-

High throughput sorting up to 3.8 m/s

-

Extended lifetime & enhanced stability

-

New generation DUOLINE™ sensor

-

Enhanced software intelligence

-

High operational flexibility

AUTOSORT™ PULSE

The dynamic LIBS solution for sorting aluminum scrap by alloy

AUTOSORT™ PULSE redefines industry standards by enabling high-throughput production of alloy scrap fractions to create green aluminum.

-

Dynamic LIBS technology

-

High throughput alloy sorting

-

3D object scanning & shape recognition

-

Single-point scan for sharper detection

-

AI-based detection of overlapping objects