TOMRA leads the resource revolution: 50 years's dedication

TOMRA China set up testing center, supply chain center, especially customer service center to eliminate the concerns of Chinese customers about the time-consuming and costly maintenance of high-end equipment imported from Europe. The localization in particular became the top priority.

“With advanced technology, excellent team and perfect service, TOMRA has created an outstanding market share and industry reputation in the competitive Chinese market over the past ten years.” Kelly proudly told us.

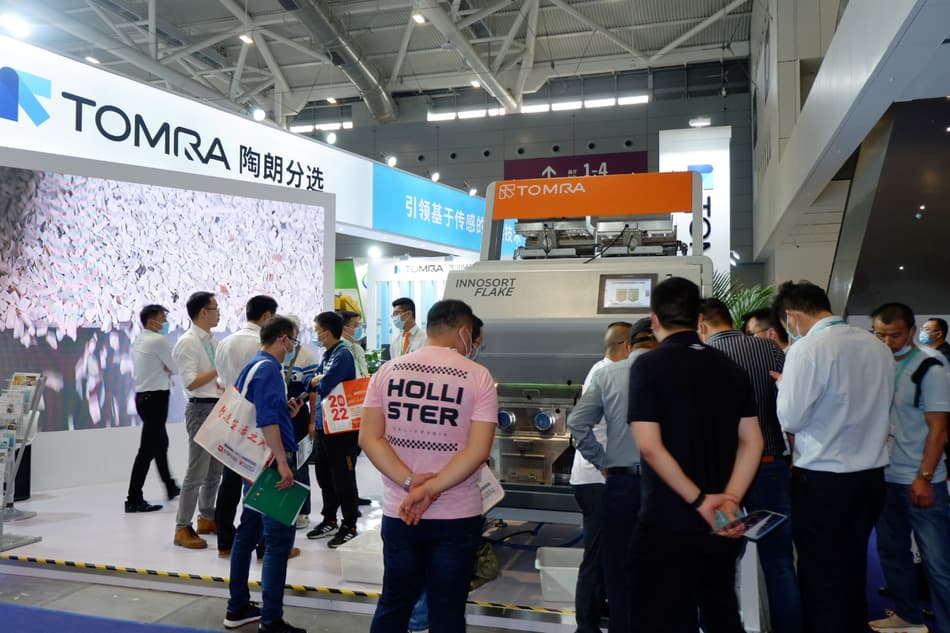

Talking about the current situation of plastic recycling technology and the market in China, Kelly said that she had contacted and exchanged ideas with many customers and industry professionals at Chinaplas, and most of them wanted to learn the latest technology and market information on waste plastic recycling, which represented an increasing demand for high-quality recycled plastics.

She is full of confidence in the prospects of the plastic recycling industry. For example, people from the world-leading brands of household products were at the TOMRA booth for in-depth communication.

They were concerned about whether the average Chinese consumers would accept recycled plastics in the packaging of household products and whether they would be willing to pay for the higher commodity prices as a result of the use of recycled materials. In Kelly’s opinion, the reuse of plastics in the FMCG sector has improved, but the quality, cost, and cleanliness of recycled plastic packaging are still controversial in the industry. More efforts should be made to promote the consumers’ trust in recycled materials. She gave some advices to encourage more consumers to accept recycled plastic packaging and take pride in using and consuming recycled packaging.

TOMRA’s leading sorting technology and expertise are well-known in the global waste management and recycling industry. Plastic recycling is one of the hot social issues nowadays. Many brands and raw material manufacturers are paying attention to waste plastic recovery. The recycling industry has an excellent opportunity for growth, which is also a significant benefit for TOMRA. However, Kelly pointed out that although the plastic recycling industry is regarded as a sunrise industry with unlimited business opportunities, its development will not happen overnight. There will be no explosive growth in the short term, and the industry will go through an extended period of evolution, despite all the hyper.

As the saying goes, you can’t make something out of nothing. Although the sorting, washing, and extrusion of waste plastics are mature technically, the recycling companies are suffering from the difficulty of obtaining waste materials, which has become a significant problem in the current plastic recycling industry.

Therefore, it is essential to establish a scientific and standardized waste plastic collection system covering transportation, terminal disposal, resource recovery, and information management. Kelly shared a success case of TOMRA helping build the Shanghai Xupu Two-Network Integration Distribution Center. The amended Law on the Prevention and Control of Environmental Pollution by Solid Wastes was introduced on September 1 last year. It requires “strengthening the integration of the Sanitation System and the Recycling System in terms of planning, construction and operation”, that is, the “Integration of the Two Networks”. Shanghai has been at the forefront of waste separation and integration of the two networks in China and has built a series of pilot projects. A dedicated plastic sorting line has been created in Shanghai Xupu Two-Network Integration Distribution Center to recycle all kinds of plastics in household waste and reduce plastic pollution.

TOMRA’s NIR sorting machine, AUTOSORT®, is introduced on the sorting line to detect and sort the mixed materials sent to the production line according to their material and color characteristics. The mixed waste plastics are sorted into transparent PET, colored PET, white HDPE, colored HDPE, other plastics and films by AUTOSORT®. The high purity of sorted materials lay the foundation for the high-value recycling.

At present, most of recycling companies in China mainly are focusing on downcycling, which is neither in line with the original intention of the circular economy nor can it provide a large number of high-quality recycled materials for brand companies. Kelly mentioned that currently, only 14% of plastic packaging is captured for recycling, and only 2% of this is recycled in a ‘closed loop’, meaning it can be reused again for the same purpose without being downgraded to lower quality plastic.

The proportion should be highly improved. TOMRA has announces commitment for 40% of all plastic packaging produced worldwide to be collected for recycling by 2030. She said that a group of leading consumer product brands and packaging companies are committed to using 100% reusable and recyclable packaging materials. Through the joint efforts of source material manufacturers, brand owners, and end consumers, plus policy support, we have the confidence that this goal will be fully achieved. TOMRA has been enabling this change through our technology and expertise for almost 50 years – we challenge others to join us and act now.

By taking part in the Chinaplas, a grand event in the plastics industry, TOMRA has fully demonstrated its corporate values of “Innovation, passion and responsibility”. Kelly told the reporter that, TOMRA currently has more than 7,400 units installed around the world, of which nearly 300 units are in China, with the largest client using 36 units of TOMRA equipment. As reported by JF PLASTICS magazine earlier this year, Guolong renewable resources Co., Ltd has purchased more than a dozen machines from TOMRA. Guo Jiawan, chairman of the company, praised TOMRA’s equipment on various occasions and expressed his endorsement for the TOMRA. Kelly expressed her gratitude to all customers, saying that TOMRA would continue to increase investment in R&D and develop high-performance equipment to help customers in the domestic recycling industry improve production capacity, achieve higher sorting purity and reduce operation and management costs through intelligent technology, thus achieving a win-win situation.

By taking part in the Chinaplas, a grand event in the plastics industry, TOMRA has fully demonstrated its corporate values of “Innovation, passion and responsibility”. Kelly told the reporter that, TOMRA currently has more than 7,400 units installed around the world, of which nearly 300 units are in China, with the largest client using 36 units of TOMRA equipment. As reported by JF PLASTICS magazine earlier this year, Guolong renewable resources Co., Ltd has purchased more than a dozen machines from TOMRA. Guo Jiawan, chairman of the company, praised TOMRA’s equipment on various occasions and expressed his endorsement for the TOMRA. Kelly expressed her gratitude to all customers, saying that TOMRA would continue to increase investment in R&D and develop high-performance equipment to help customers in the domestic recycling industry improve production capacity, achieve higher sorting purity and reduce operation and management costs through intelligent technology, thus achieving a win-win situation.

Kelly added that when she had joined TOMRA and entered the resource recovery industry eight years ago, the plastic recycling had not been taken seriously by most people. However, it has become one of the focuses of the industry today. “A promising era for plastic recycling begins. It’s time to rethink the take-make-waste systems of the linear economy and navigate through the headwinds impeding the transition to a circular economy. Together we are well-positioned for upcoming megatrends and ready to continue leading the resource revolution.”