Artificial neural networks changing the game in wood recycling

Jose Matas - Segment Manager Wood

Experts in the field of AI and major players in the recycling are convinced that machine intelligence can help solve some of the panelboard industry’s biggest challenges. While AI is quite the buzzword today; it is actually nothing new. It has existed since the 1940’s, but only with the emergence of personal computers and greater computing power has it taken on a completely different meaning. While we might not know it, we interact with AI on a daily basis: whether searching Google, using navigation systems to find the fastest route to our destination, or deploying robots to carry out mundane tasks, and much more.

Sorting systems – AI’s gateway into recycling

We are living a moment of technological revolution, where AI-driven solutions become increasingly powerful and software the key tool to improve recycling performance. As for waste wood recycling, plant operators often face the challenge of scale.

They need to recover as much recyclable waste wood as possible and create the purest material fractions to scale and meet the market's demand. Thanks to Deep Learning technology, it is now even possible to detect and separate wood category types, such as processed wood and non-processed wood.

Deep Dive into Deep Learning

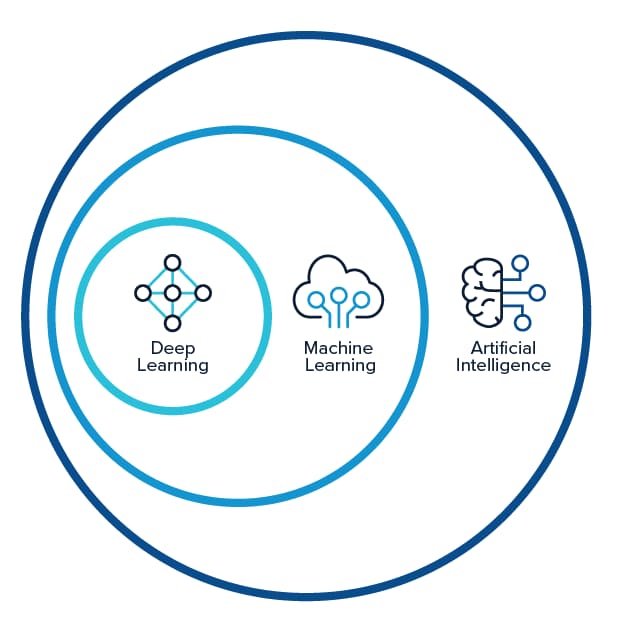

Artificial intelligence can be defined as any technique that enables computers to mimic human intelligence, using logic, if-then rules, decision trees, and machine learning. Deep Learning is a subfield of machine learning that can process large volumes of complex data, which is beneficial for sorting applications of very heterogenous waste streams. Unlike Machine Learning, Deep Learning does not require active feature engineering and is able to extract additional characteristics from the picture if trained with sufficient data. Considered the most promising approach, it unites numerous concepts, delivering future-forward solutions for diverse sorting tasks:

One of its concepts is image classificationwhich allows a sorting machine to categorize what it sees in a picture, such as MDF. Since the object’s position delivers crucial information for the classification and sorting decision, methods such as traditional image processing are applied to crop out objects before image classification.

Another concept of AI is object detection. Knowing that the picture contains a wood chip is not sufficient for a fact-based and precise sorting decision. The machine also needs to know exactly where the material is located on the conveyor belt. Object detection pinpoints the position of the wood chip on the belt.

Semantic segmentation is yet another method that carries out pixel-level classification and delivers more detailed information on the object's position. Since the wood chips are fed on the conveyor belt in bulk, they can easily overlap and negatively impact the classification and sorting decision.

There is another approach called instance segmentation that demarcates targeted materials for high precision sorting. As a result, two overlapping objects of the same material class can be detected as individual instances.

A powerful tool for particleboard manufacturers

As noted in our previous articles, recycling waste wood is a valuable business opportunity and a viable means to mitigating the environmental impact of using primary resources. Once waste wood is collected, it undergoes an extensive purification process to remove unwanted materials, such as stones, metals, or inert materials with X-Ray sorting technology. The clean woodchips can then be further sorted by material type according to operator's requirements.

Unlike conventional sorting methods, the combination of the Near-Infrared and Deep Learning technologies enables peak performances in sorting accuracy and purity levels. With sophisticated sensors and the power of artificial neural networks, the sorting system is trained to distinguish different material types, such as processed wood and non-processed wood. Since only the purest non-processed wood fractions are suitable for the production of high-quality particleboards made of recycled content, separating wood by type is an indispensable step in modern particleboard manufacturing and wood recycling plants.

A deep dive into deep learning

By Sebastian Solbach, Team Leader Application Development Deep Learning at TOMRA Recycling

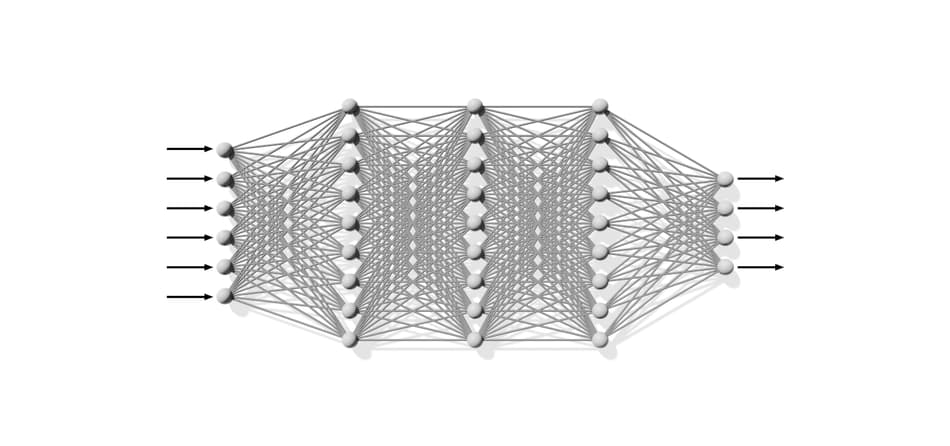

Deep Learning technology works based on artificial neural networks consisting of artificial neurons. Grouped in multiple layers of different functions, artificial neurons networks learn how to identify and classify objects. In fact, deep learning can extract a hierarchy of features from raw input data and group it into different categories of data.

To make use of deep learning in sensor-based sorting, our engineers meticulously train the network by exposing it to thousands of annotated images. Once a trained network receives information about an object scanned by the sensors, it uses the features extracted from the annotated images and connects it to the material, predicting what the scanned object can be.

Recent breakthroughs in object detection are enabled by convolutional neural networks, a special type of artificial neural network made up of varying cascades of convolutional and pooling layers.

The first layer type (convolutional layer) extracts distinctive features from a scanned object. These features can be edges, textures or any other abstract object properties.

The second layer type (pooling layer) condenses the image information, enabling subsequent convolutional layers to look at the bigger picture and detect additional features, like the shape of a whole object.

After all relevant object features have been extracted by the first and second layer types, the last part of the neural network, which can be “fully connected layers”, assigns/classifies the object into a wood type.

All layers can be combined and repeated as required to carry out the respective classification task and reach the desired result.

Artificial neural networks for greater flexibility

The performance of deep learning technologies is based on artificial neural networks. Trained with thousands of images of objects that can usually be found in the waste stream, artificial neural networks hold a pool of object information they draw on when detecting and separating materials. Based on the extensively annotated data, the system recognizes patterns and properties of individual wood chips and instantly connects this information with data scanned by sensors. Wood chips are then categorized by material type and separated according to the customer-defined sorting task.

Deep-learning-based systems offer significantly more flexibility to the operator, allowing them to choose the types of materials they would like to target in the sorting process. For example, MDF and plywood can be recovered from processed wood. Operators can take advantage of the sorting flexibility to recover more types of recyclable materials and create new revenue streams.

In conclusion, combining advanced NIR systems and Deep Learning gives particleboard manufacturers and wood recyclers a competitive edge in optimizing their operation and reducing costs of limited and expensive primary materials.