TOMRA highlights full wood sorting solution at LIGNA

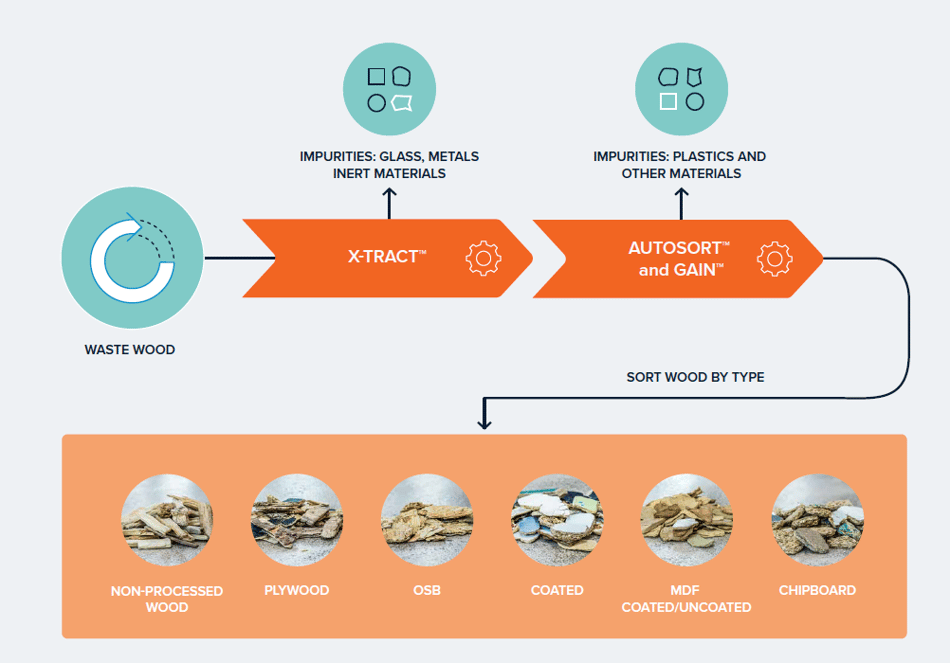

The company’s wood

sorting portfolio comprises, among others, X-TRACT™ for the recovery of clean wood

chips from waste wood and AUTOSORT™ with GAIN™ deep-learning technology for sorting

by wood type. Wood processors and recyclers using a combination of both systems

can reap considerable benefits in the production of high-quality mono fractions

of Wood A and clean Wood B and MDF.

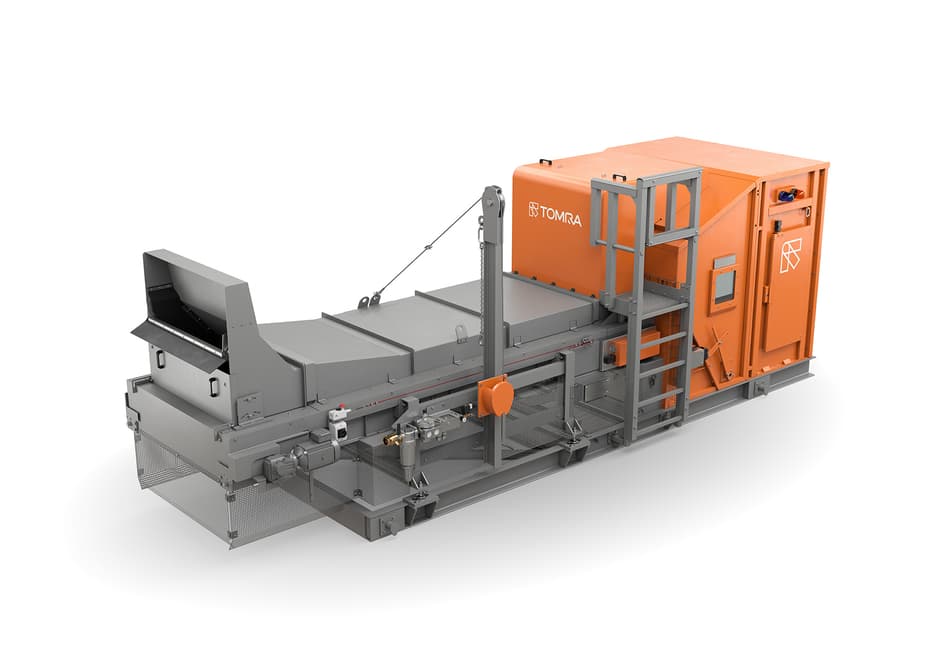

In the first cleaning step, TOMRA’s X-TRACT™ removes any contaminants from waste wood to create a pure wood chip fraction.

Following the establishment of a dedicated team for the wood segment, TOMRA has also recently expanded its service team to ensure minimal downtime and best-in-class service. Markus Brauer, who comes with long experience in TOMRA’s Mining business, has been appointed Team Leader Field Service Wood explains: “I have been working with X-TRACT™ for 11 years. With my expertise gained in this challenging environment, I supported the development of the machine. TOMRA’s commitment to constantly improving performance is evident with the latest updates. The machine delivers reliable results and is easy and safe to maintain. Our customers value the competitive edge the machine gives them.”

TOMRA’s new X-TRACT™ for wood sorting delivers reliable results and produces a fraction that can be further processed into mono materials that meet manufacturing standards. To deliver recycled materials that comply with stringent quality standards, recyclers must go one step further and recover different material types from the wood chip fraction. Especially non-processed wood is high in demand and indispensable in particleboard production. Until recently, separating wood by material type has been a major bottleneck in increasing recycling rates. Thanks to the latest innovations in deep learning sorting technology these challenges can now be overcome.

As a frontrunner in the industry, TOMRA was the first

to introduce deep learning-based technology for sorting wood by material type

in 2021. Available as an add-on for its AUTOSORT™ units, GAIN™ deep learning

technology is trained to distinguish different material types, such as

processed wood and non-processed wood.

Thus, recyclers using the latest

technology profit from operational flexibility and have the means to create

high-purity fractions of one material type. Jose Matas, Segment Manager Wood at

TOMRA Recycling Sorting states: “Combining our X-TRACT™ and AUTOSORT™ with GAIN™,

recyclers can profit from a powerful and future-forward wood sorting solution.

The

materials recovered meet manufacturing standards and help overcome current

challenges like price volatility and the lack of sufficient high-quality

recycled materials. We have a longstanding legacy in the wood segment and we

will continue to best support the industry in unlocking new opportunities – and

they are manifold.”