KATO260 and LUCAi®

Color Sorter

Soft Sorter

CURO

TOMRA Neon

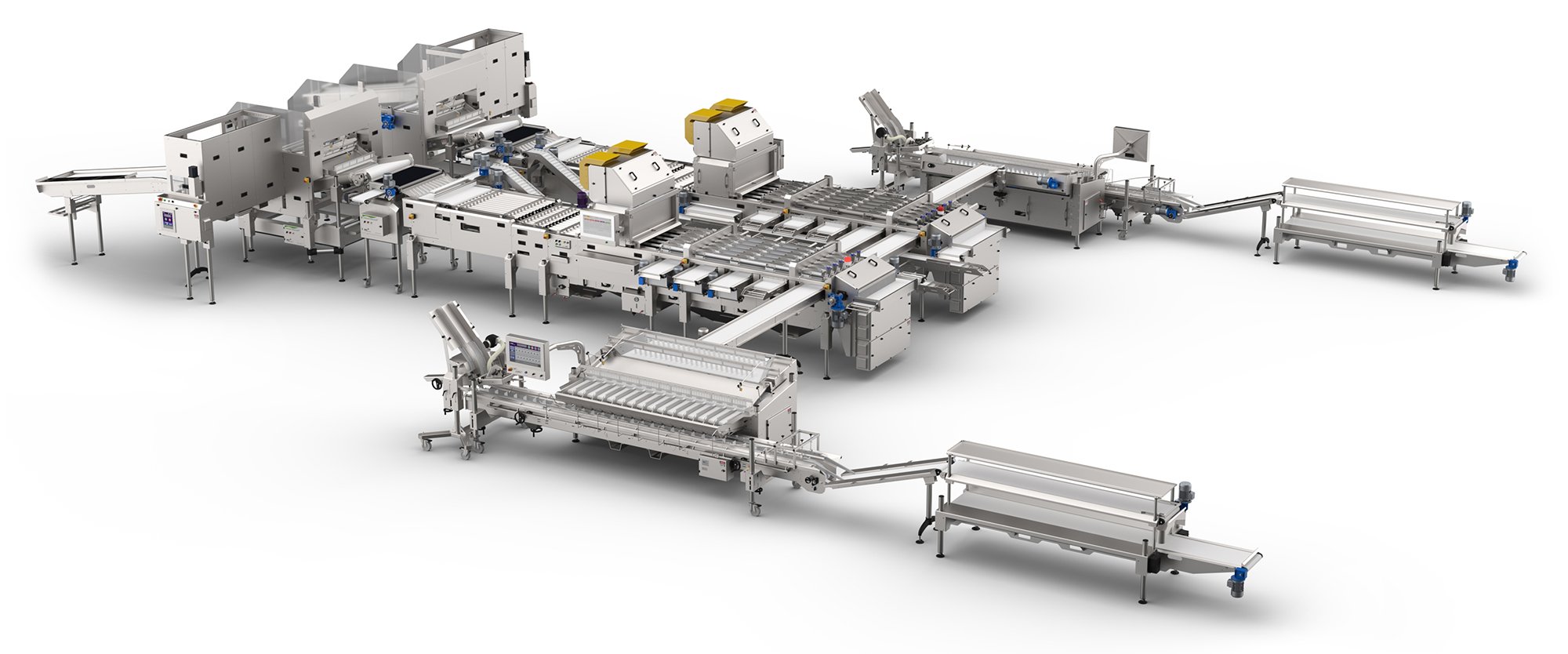

Integrated turnkey line

Click the touchpoints on the render for more information

Click on a touchpoint for more information

Infeed

Our infeed front of line loading systems include automated tipping and dumping solutions as well as debris and small fruit removal components that optimise the capacity of the processing line while maintaining gentle handling of delicate blueberries.

Sorting and grading

Our sorting and grading solutions are highly suited to blueberry packers eager to meet ever changing market demands. Our grading options are easily integrated with all of our other solutions enabling growers and packers to increase business through superior selection and better guarantee of shelf life.

Filling and packing

Our filling and packing solutions are highly suited to blueberry packers with demanding filling requirements. Our solutions are easily integrated with all of our other solutions and accommodate versatile packaging types from punnets, clamshells, bags and boxes.

Our blueberry sorting machines

Blizzard

TOMRA 5C

Customer story

Logofruits, Portugal

Logofruits started off about 4 years ago in Alcácer do Sol with 15 hectares of farmland. Since then, they expanded to include the Odemira region with an eye on a wider production and harvest season. Logofruits' state-of-the-art plant allows them to provide their customer base with quality products fitting every customer's specifications. Additionally, they also provide their services to third parties from Chile, Peru, and South Africa. Thanks to machines such as the KATO 360, LUCAi™, and CURO, their new integrated TOMRA Food sorting and grading line allows them to boost the automatization process of their sorting and packing.

Customer story

Ambrosia Citrus Estate, South Africa

Ambrosia Citrus Estate reached out to TOMRA Food wanting to find an integrated packing solution for their blueberry line.

Thanks to our wide array of solutions, we were able to help Ambrosia with:

- Sizing and grading their product to answer their customer's needs.

- Steering away from the need to grade the product by hand.

- Providing feedback on the blueberries' softness, for which they previously had to rely on the pickers.

- Meet the request for increased processing speed as fresh product is supplied more rapidly.

Get in touch

Operational costs continue to increase, and every little saving makes a difference.

Our automation works smarter, wastes less, and optimizes your lines to ensure quality is consistent and potential recalls are thing of the past.

Speak with us to learn how you can make Every Resource Count!™

In the spotlight: blueberries

How modern grading and packing solutions enable blueberry packhouses to gain and retain competitiveness

.png?h=1333&iar=0&w=2000&hash=6872C67433AB986F133FA3338DE56FC3)