Get in touch

Speak with us to learn how you can make Every Resource Count!™

TANN Marchtrenk, Austria’s largest producer of meat products, uses the TOMRA QVision as part of its innovative fat analysis. As a result, the in-line fat analysis process is improved and optimized to deliver a uniformly high-quality product. With 1,000 employees, the company produces specialty meat and sausage in six regional plants exclusively for the 1,600 locations of Austrian supermarket, SPAR. The production plant, which was originally built in Marchtrenk in 1978 and connected to the regional centre of the SPAR Österreich Group there, was extended several times and completely renewed in 2005.

At SPAR, a large part of the meat sales continues to take place at the service counter. However, self-service sales are growing at a faster rate.

“Consumers are increasingly turning to self-service products. This is also due to the fact that we have built up a high degree of trust through first-class quality over the past ten years”, emphasizes Helmut Plakolm, TANN Marchtrenk’s plant manager. The exemplary quality assurance system in TANN’s meat production ensures flawless products.

“Our process chain is simply right. That’s why we have very few complaints,” explains Helmut Gerner, Production Manager.

In order to maintain this system, optimizations are continuously carried out that contribute to securing and improving quality. This is because consumers’ demands are rising when it comes to their meat consumption.

“The per capita consumption of meat is stable to slightly declining, due to current nutritional trends. At the same time, various consumer groups have emerged, for whom very different aspects are important. With the purchase of the corresponding products, people utter personal convictions, e.g. a special awareness of nutritional, environmental or animal welfare,” says plant manager Helmut Plakolm to describe the current situation on the Austrian meat market.

In order to meet these differentiated consumer demands, SPAR offers six variants of minced meat in the self-service area. In addition to the classic varieties of mixed or minced beef meat, there are two varieties of low-fat minced meat, two variants of organic minced meat and one variant with special animal welfare labeling. All six varieties together achieved a 25 percent increase in volume last year.

“In the overall stagnating Austrian meat market, growth can only be achieved today by gaining market share.” Says Plakolm. “For us, this means we have to continuously strive to be the best and convince our consumers with first-class products.”

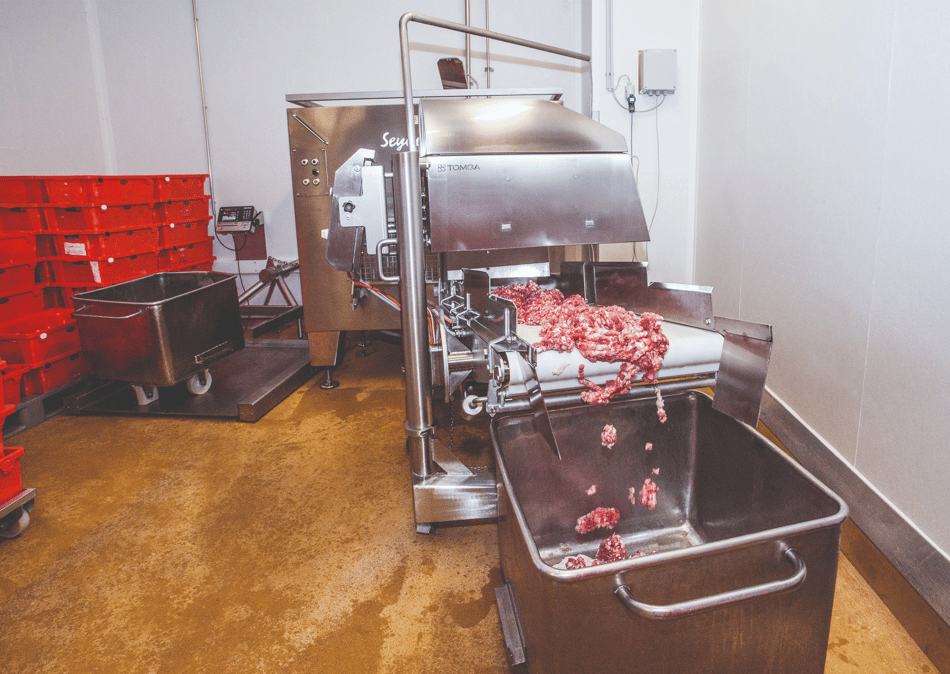

Reliable compliance to the proscribed fat content is ensured with TOMRA QVision. The recipe is applied precisely and the quality of the finished product is not subject to fluctuations. The machine also helps manufacturers comply with legal requirements, such as maximum fat, protein and collagen levels for minced meat.

The TOMRA Sorting Food division is part of TOMRA Sorting, which is the world’s leading supplier of sensor-based sorting systems for recycling, mining and other industries with more than 11,300 installed systems. This division specifically develops innovative solutions for the food industry.

“The machine used at TANN uses the transflexion technology developed by TOMRA. Transflexion enables in-line analysis of fresh or frozen pork, beef or poultry meat. The fat content of the meat is easily determined. This enables users to improve their processes through more targeted raw material acquisition and better supplier control,” explains Lars Povlsen, Sales Manager at TOMRA Sorting Food.

Thanks to its compact design, the state-of-the-art TOMRA analyzer takes up little space in TANN’s production facilities. It can process up to 30 tons of meat per hour - either grinded, in sections or in pieces of different sizes. In the fat analysis, the product flow through the plant is recorded from beginning to end, so that TANN employees can make adjustments to the fat content of the minced meat mixture directly during operation. This works easily at the push of a button.

Before purchasing a TOMRA QVision, TANN used the machine in a trial phase.

“Our employees were immediately able to cope with the uncomplicated operation. This convinced us.” (Helmut Gerner, Production Manager SPAR Marchtrenk)

The fat determination with the TOMRA QVision analyzer ensures the production of minced meat is consistent quality and, at the same time, guarantees reliable control of the production process for individual suppliers. It also simplifies later evaluation, as the data collected can be retrieved and exported at any time in the form of reports.

“Our customers can be sure that their suppliers will actually provide them with the raw material quality they pay for. At the same time, they can optimize their purchasing processes,” explains Povlsen.

In-line control makes it possible to use less lean meat. As a rule, the meat mixture is first set too lean during production in order not to exceed the fat values prescribed by the recipe. During production it is easier to increase fat than to reduce fat. However, this usually involves a higher use of more expensive lean meat than is actually necessary. Real-time analysis with immediate adjustments during production and without downtime can significantly optimize this process, and thus lead to significant savings. The results have convinced TANN Marchtrenk. Starting in the spring of 2018, two more systems will be in operation, one at the Graz plant and one at Wörgl.

With the QVision analyzer, TANN Marchtrenk has opted for the complete version of the system and is therefore well prepared for future requirements. In addition to the fat content, the instrument can also analyses the collagen, protein and water content of meat.

“If Austria were to follow Germany, where the relationship between collagen and meat protein must be indicated on the packaging, this can be implemented without any problems with the existing installation,” concludes Plakolm.